Screen Print Logo:

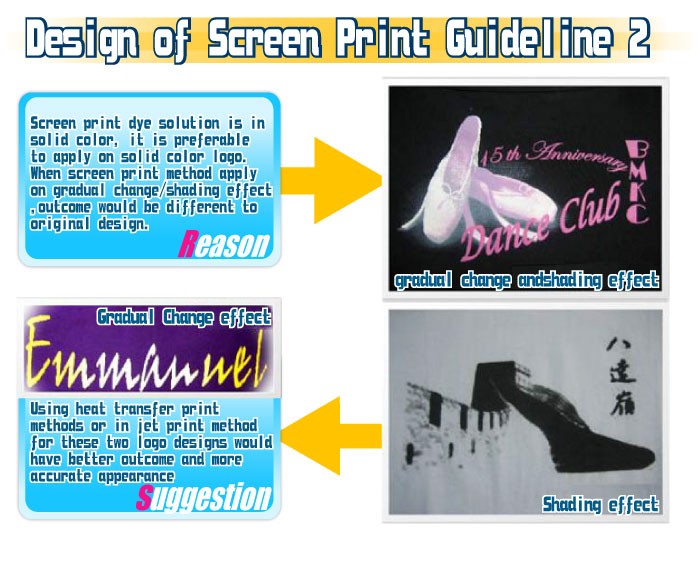

2.Screen Design Guidelines 2

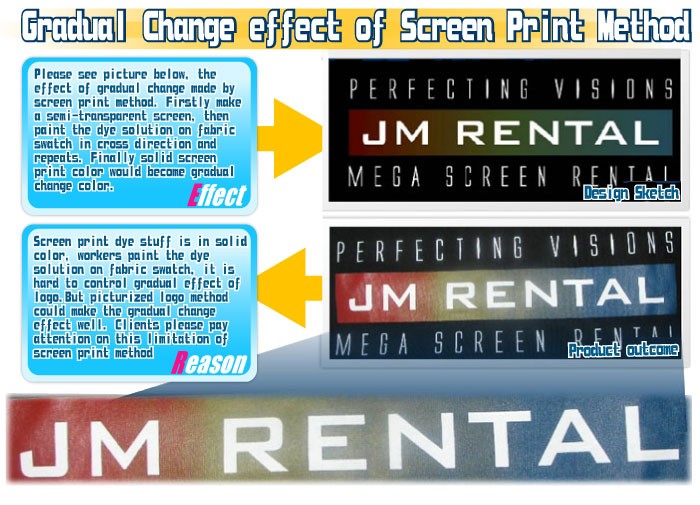

3.Screen transition effects

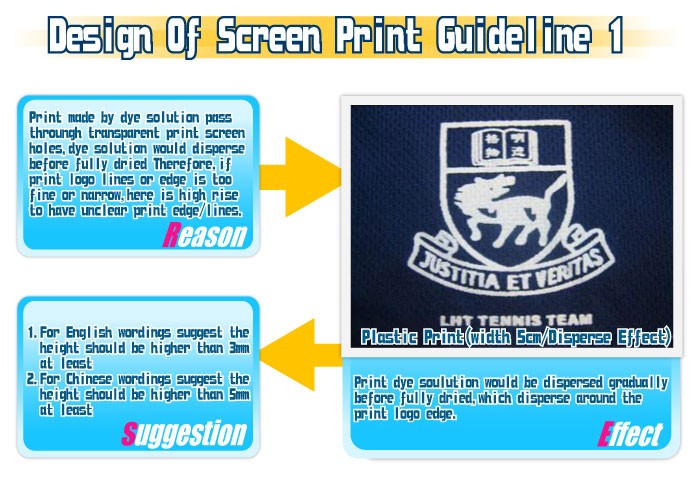

Design Of Screen Print Guideline:

1. Individual print FILM and FRAME must be issued for each silk screen print color. Therefore, price will increase in proportion to the number of colors in the logo.

2. In general, oil-based screen print (膠漿絲印) should be applied for white and light color fabric. While water-based screen print (水漿絲印) should be applied for black and dark color fabric.

Oil-based Screen Print (膠漿絲印):

Ø Diffusion effect is considerably more obvious, and the paint will extend to areas where it is not supposed to have the logo design or overlap with other patterns inside the logo (e.g. the logo is with a complete pattern but with many small areas inside the logo which show the fabric as ground color, then such diffusion effect may fully fill up such small areas which resulted that the entire logo is blur.).

Ø Also, when the logo is printed and at the time the paint is still wet, there is possible that dust in the air may fall into the logo area and being trapped in the logo, thus result in some dusty & hairy effect on the logo.

Ø Oil-based screen print exhibits a layer of plastic-like coating on top of the fabric surface. This layer of coating has potential to have small cracks and color fading after repeated washing; this is due to the physical limitations by the nature of the product.

Water-based Screen Print (水漿絲印):

Ø Water-based paint will be directly absorbed by the fabric, thus colorfastness is better. However, the garment will become washed out after repeated usage and washing. Therefore, the logo colors will also fade as time goes by.