Digital Printing:

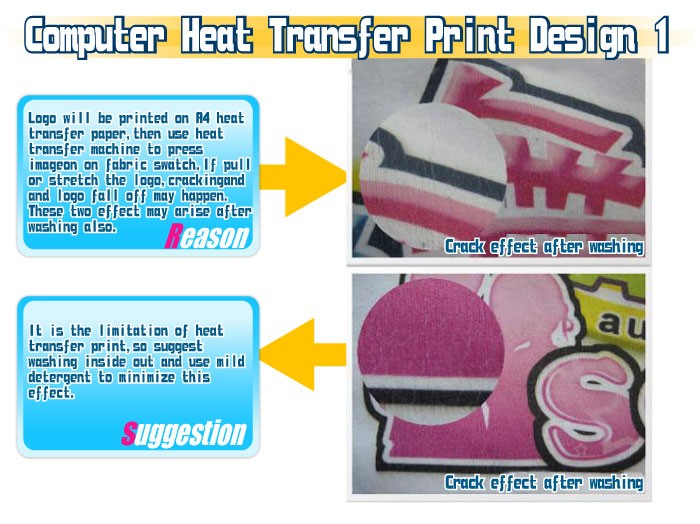

1.Design Guidelines for a Computer Transfer 1

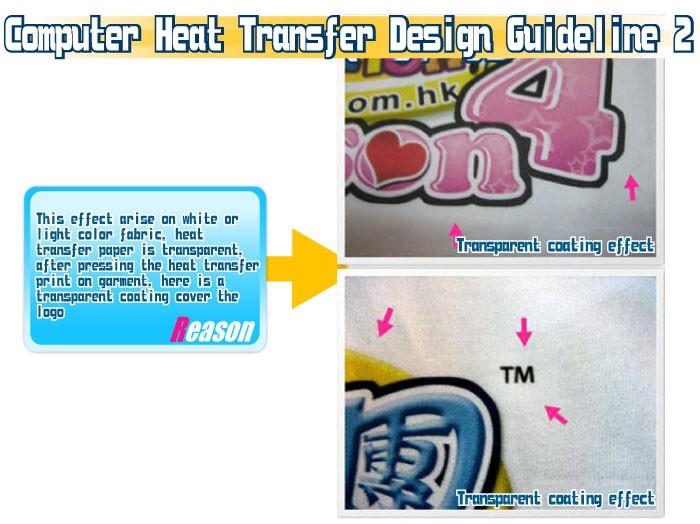

2.Design Guidelines for a Computer Transfer 2

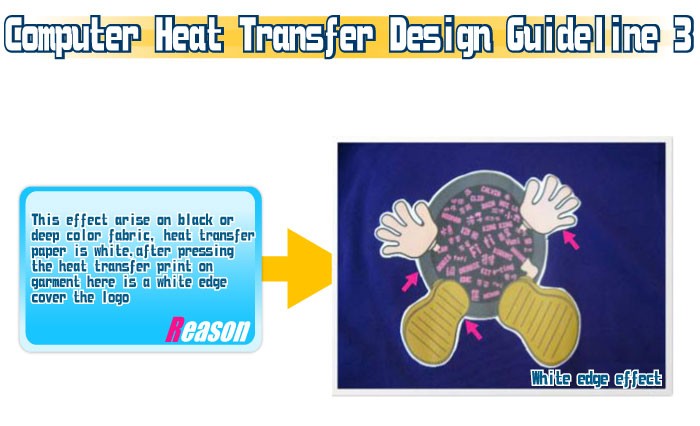

3.Design Guidelines for a Computer Transfer 3

Computer Heat Transfer Print Design:

1. Logo is printed out by regular printers using special designed heat transfer paper. Then the logo will be transferred to the garment fabric panel by heat set printing machine.

2. White heat transfer print paper will be used if the fabric is white and light colors. Therefore, the logo background and the peripheral area will be in white color.

3. Clear heat transfer print paper will be used if the fabric is black and dark colors. Therefore, a clear plastic-like coating will cover the logo after printing.

4. Logo size is limited to be A4 because the heat transfer print paper is available in A4 size only.

5. Gradient, shadow effect and multi-colored logo could be available because the logo is print out by regular printer. However, the actual colors from the print out shall vary when compare with onscreen viewing of the logo.

6. The entire heat transfer paper or the logo-shape will be cut out and then heat offset onto the garment panels. The limitations are that if the logo is forcefully stretched, there maybe potential slightly peel off and cracking, this may also happen after repeated washing. It is suggested to turn inside out and use mild temperature water during washing in order to minimize such situations.